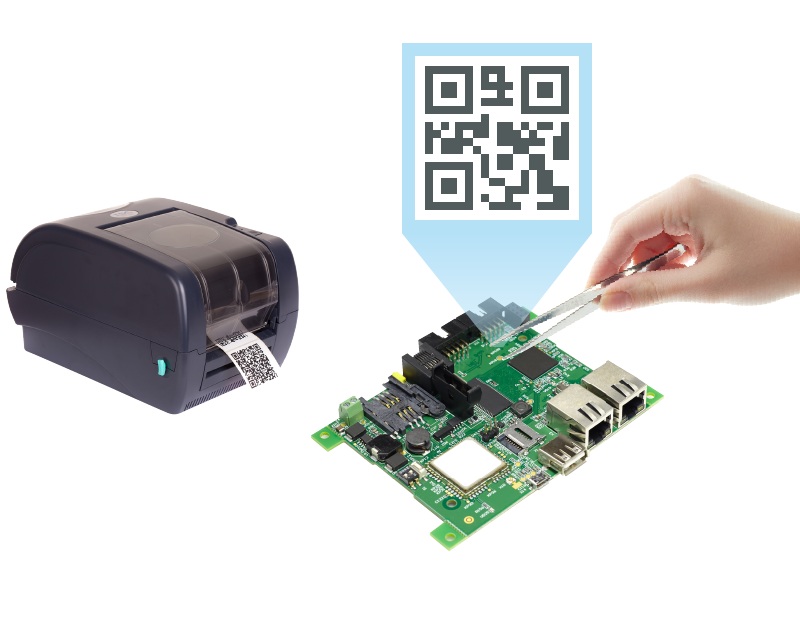

To serve the production process well, we have created a production management system based on QR code technology. We've packaged the system and made it completely applicable to your production application.

In each PCB project, each board will be identified with a unique QRCODE code

QR code scanners are mounted in all locations to monitor every step of PCB production, from SMT to product release (see below...).

Architecture system

The hardware system consists of a slave node, a master node, and a gateway.

Description

Specifications

- Decoding Ability

- Resolution: 0.10mm (4mil)

- Reading Distance :25 - 250mm

-Interfaces: USB2.0 \ CAN

- Type of Illuminant: 617nm LED(Aimer), 6500K LEDs(Illumination)

- Scan Angle: Roll:0-360°, Pitch:±65°or greater, Yaw:±60°or greater

- Scanning angle Inclination angle: 34°, Elevation angle 26° Print Contrast 30% minimum reflective difference

- LED Indicator:Buzzer and bi-color light: Red-power, Blue-decoding Successfully

- Operating Temperature:-20 degrees to 55 degrees

- Storage Temperature:-40 degrees to 65 degrees

- Temperature Humidity:5% to 95% Relative humidity, Non-condensing

- Light Levels:0-85000LUX

- Operating Current :120mA

- Operatuing Voltage: 5-12V

With this device, you can easily integrate handheld scanners into your system via USB communication

Displays location and scan steps in real time, and will display an alert when the scan steps are wrong.

.png)

All defects in the production process will be recorded, and promptly reported to the manager, helping to promptly handle the problem.

.png)

.png)